Expert sources estimate the global word losses of metal from corrosion in the amount of at least 15 billion USD per year.

The economic damage from corrosion is made up of the loss of the cost:

- of the Metal in "live weight" in quantitative terms in tons;

- of repair work to restore the areas of equipment affected by corrosion;

- of replacing equipment that has fallen into disrepair entirely due to corrosion and the cost of its delivery;

- of materials, spare parts, their delivery to the site for the repair of equipment and / or for its installation;

- of Construction and installation works, restoration and major repairs;

- and losses associated with production downtime of technological installations;

- and losses associated with the reduction of the service life of the equipment;

- and losses associated with changes in the economic performance indicators of investments and capital investments in production.

Corrosion control is directly related to:

- ensuring the safety of operation,

- ensuring trouble-free operation,

- reliability,

- the operational readiness of the equipment.

Reducing the rate of metal corrosion, increasing the service life of equipment are very important economic importance for any production, and especially for Refineries, Petrochemicals and Chemicals, where corrosive environments are particularly active.

Cold Ph Tech ® - Cold Phosphating Technology to protect metal from corrosion

The mechanism of Cold Ph Tech working:

After treatment, a continuous gas-tight film of metal phosphates is created on the metal surface. This film serves as a barrier between the metal and the corrosive medium flow. Adhesion is at the level of chemical bonds of the metal boundary layer with the formation of strong refractory compounds of metal phosphates on the surface. The phosphates form a stable continuous film with a crystalline three-dimensional lattice.

Film color: from silver-gray to black blued-steel color.

Operating temperature - up to 600 C.

Properties of Phosphate Film on Carbon Steel:

Cold Ph Tech, when applied to steel, cast iron, galvanized and aluminum surfaces, forms a solid, stable, crystalline 3-dimensional polymer film made of phosphates that have a chemical bond with metals that are part of the alloy of steels.

The film made of metal phosphates after applying Cold Ph Tech has the following properties:

- Coating Continuity and Gasproof with minimal porosity of the film;

- No Internal Stresses that can destroy the film from the inside;

- Strength, Hardness, Wear Resistance of the surface;

- Inertness and Chemical Resistance;

- Insolubility in water and in organic solvents;

- Thermal Stability in the temperature range from - 60 °C to + 600 °C, depending on the composition of the metal to be processed;

- Non conductivity at a voltage of up to 500 volts, which slows down the corrosion process in the presence of stray currents.

Cold Ph Tech can be used for corrosion protection of load-bearing and enclosing metal structures operating in atmospheric conditions:

- It has unique adhesive properties at the level of chemical bonds with metals;

- Ideal for the first layer in multi-layer paintwork systems;

- Increases the service life of finish paint coatings by 1.5 - 2 times;

- It forms a film of metal phosphates, which is compatible with almost all types of paint coatings, including organosilicon, ceramic, powder and other types of coatings;

- It can be used to protect against rust formation, to preserve metal surfaces between different long stages of repair work, stretched over time in the repair schedule;

- It can be used for anti-corrosion treatment of welds immediately after the welding work is completed.

- It can be applied on surfaces with traces of rust and tightly bonded scale. A high degree of surface cleaning is not required. Iron oxides (rust) undergo transformation.

Cold Ph tech can be used to protect against corrosion and to combat corrosion on the external and internal surfaces of process equipment, pipelines and flues operating in aggressive environments in the liquid and gaseous phase.

- The objects of application of Cold Ph Tech can be all sections of pipelines, tanks, heat exchangers, furnaces, boilers, reactors, air heaters, refrigerators and other devices that have an increased corrosion rate.

- Due to the fact that the operating temperature range covers T = +600°C, Cold Ph Tech can be used to protect the convective sections of furnaces and air heaters, evaporators and economizers of boilers operating in gas environments with temperatures close to the dew point.

- It is combined with the procedures of thermal tempering of welds and is applicable for anti-corrosion treatment of welds immediately after their execution.

- It is applicable as a means of anticorrosive protection under layers of thermal insulation of technological equipment with a high temperature on the surface.

As a result of using the Cold Ph Tech, the Customer will acquire:

- Increasing the useful life of load-bearing and enclosing structures while maintaining their basic functions (strength, safety).

- Increasing the service life of finishing and painting coatings by 1.5 - 2 times.

- Increase in the wear resistance and hardness of the metal surface due to the formation of a phosphate film on the metal surface.

- Reducing the cost of periodic repair and restoration of paintwork and other anti-corrosion protection systems.

- Continuity of processing by coating of all metal surfaces of process equipment in contact with a corrosive process environment = protection against unpredictable pitting (ulcerative) corrosion of pipelines, tanks and other equipment of refineries and petrochemicals.

- Increasing the useful life of technological equipment while maintaining its basic functions (strength, tightness, safety).

- Reducing the cost of repairing and restoring process equipment and pipelines.

- Improving the quality of repair work, including welding work.

- Reducing the corrosion rate of process equipment operating in corrosive environments.

- Reducing the cost of process reagent anti-corrosion treatment of plant equipment during their inter-repair run.

- Reduced unit operating costs. Reduction of the specific consumption of resources used for the production of a unit of production or per unit of capacity of a technological process.

- Improving the economic performance of the enterprise. Increasing its investment attractiveness.

Specialists of "Green Ray Ltd." took part in the traditional Council of Chief Mechanics of Refining and Petrochemicals of Russia and the CIS, which was held in an offline format on a closed forum platform in the period from December 01 to December 25, 2020.

The Report was presented to the attention of the Council of Chief Mechanics on the topic:

The details can be found at the link: Meeting of Chief Mechanics - 2020.

The following issues were highlighted in the report:

- The value and importance of corrosion control;

- Features of corrosion of equipment of the Refining and Petrochemical enterprises;

- Film-forming anti-corrosion agents;

- Cold phosphating technology using the Russian product;

- Description and areas of Cold Ph Tech using;

- Tests, regulatory documents and permits for the Cold Ph Tech composition;

- Methods of application, technical characteristics and properties of the Cold Ph Tech and the film it forms on the metal surface;

- The effects achieved as a result of the implementation of Cold Ph Tech;

- Protection against external corrosion of load-bearing and enclosing structures at Refineries and Petrochemicals;

- Corrosion protection of the internal surfaces of the process equipment of Refineries and Petrochemicals;

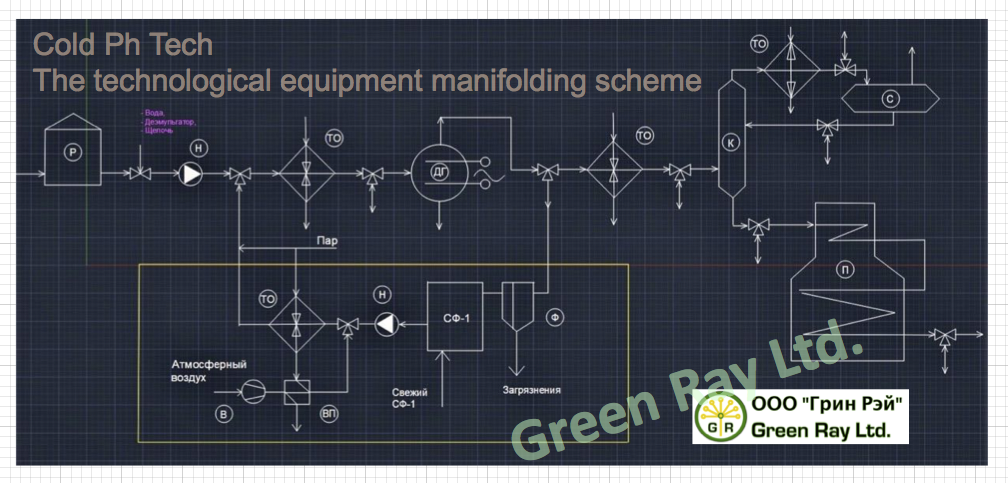

- Scheme of anticorrosive treatment of internal surfaces of technological equipment;

- What benefits does the use of anti-corrosion treatment with Cold Ph Tech composition bring to the customers?

- Automatic corrosion control systems;

- Proposals for the organization of anti-corrosion measures.

The on-line monitoring and corrosion rate control system will allow you to react sensitively to changes in the chemistry of gas-liquid production flows and adjust the program of reagent treatment of equipment.

Download the Cold Ph Tech brochure →Cold Ph Tech

The Cold Ph Tech product was also presented at the IV International Conference of JSC "VTI" on Solid Fuels in April 2022, as well as at the Meeting of the Council of Chief Power Engineers of Oil Refining and Petrochemical Enterprises of Russia and the CIS in October 2022.